Interested in learning more about our international boarding ramp for wide body aircraft, booking a demo, or discussing something else?

Call us or complete the form below and a member of our team will get back to you.

(UK) +44 (0) 1952 291220

(US) +1 (678) 737-6181

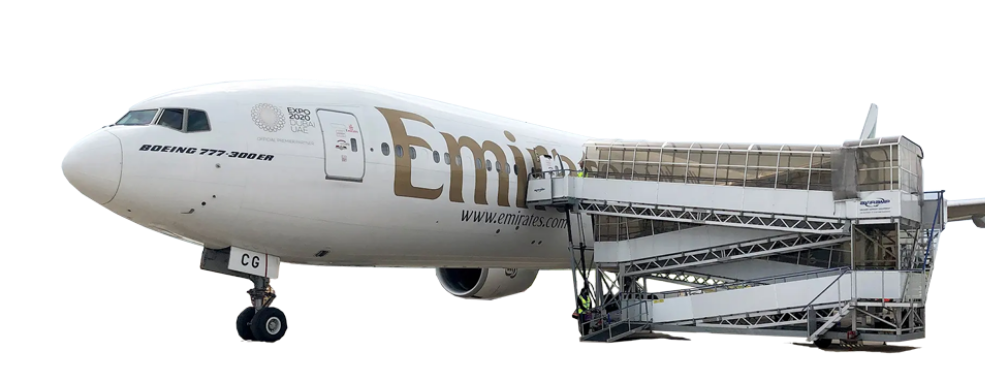

When you’re dealing with the world’s biggest passenger jets like the Airbus A380, Boeing 777, Airbus A350, Boeing 747, Boeing 787, Airbus A330, and Airbus A340 you need boarding equipment that can actually handle them. That’s where Aviramp’s International Code E compliant ramp come in.

We’re the only manufacturer that builds ramps for these heavyweight wide body aircraft. While everyone else focuses on the smaller planes that budget airlines use, we’ve cracked the challenge of safely loading passengers on and off the giants of international aviation.

Our code E compliant International ramp work for airports and ground handling companies who need reliable passenger loading solutions for wide body aircraft.

Anyone who’s wobbled up aircraft stairs in the wind knows they’re not ideal. With Code E aircraft, you’re talking about significant height differences and steep climbs that get harder as passengers age or struggle with mobility.

Our ramps change all that. The non-slip surface means safety in wet weather and the gentle angle makes boarding genuinely comfortable rather than an endurance test. Proper guard rails and handrails give people something solid to hold onto.

For wheelchair users and anyone with mobility challenges, the difference is transformational. No waiting around for special lifts or feeling like a burden – just straightforward, dignified access like everyone else gets.

Ground crews working with these massive aircraft know that time is money. These planes cost serious money to operate, so every minute saved during turnaround matters.

Our ramps dock faster than traditional stairs and one person can operate them. That means less hanging around, quicker passenger flow and aircraft back in the air sooner. They can even work as a fixed air bridge from the terminal building down to the apron area.

The maintenance side is refreshingly simple too. We handle the installation, train your people, and because these ramps work with every major Code E aircraft type, you’re not juggling different equipment for different planes.

While other manufacturers stick to the easier, smaller stuff, we’ve put in the engineering work to handle the wide-body aircraft that other boarding solutions simply can’t cope with.

The Aviramp is really easy to use, a single person operation by either tiller arm or remote control

Aviramps are designed to be single person operated, even the ramps for wide body aircraft.

Yes

The flooring is manufactured using a unique patented formula designed to prevent slippage in all weathers.

Yes, with the stabilisers deployed there is no movement.

Yes, if you choose the extra wide platform option.

The ramps are all set to a patented 8 degree switch back design

Yes, this can be achieved via the mechanical pawl lock system.

The Aviramp is best utilised on the remote stand that it will be most frequently servicing, however, as the unit is self propelled it can be moved to a central location between turnarounds.

Our ramps have all been wind tested to 41 Kts, 47 Mph, 75Kmh. Please watch this video to show you more about the wind and jet blast tests

There are Aviramps currently in operation in temperatures of -15°C The oil specification is altered for the operational climate. Our batteries are also designed to operate at sub zero temperatures. If you choose a diesel Aviramp, we can also offer a cold start kits as an optional extra.

There is minimal maintenance required our ramps, for example checking bolts and hinges. We supply inspection and maintenance guidelines upon installation. We also offer service inspection plans – please ask the sales team at sales@aviramp.com for more details. If you choose an AHM model, all of the relevant checklists will be provided to ensure compliance.

On all models the entry ramp can be stowed and the top ramp can be secured in its lowest stowed position.

There are no restrictions on how far an Aviramp can be moved, however, our recommendation is to keep the Aviramp in close proximity to where it will be used.

Aviramp can be towed at a limited speed (8 KPH), however we recommend driving the unit between a maximum of 3 stands – excessive towing speed can result in damage to the braking system

We offer both solar and diesel solutions to suit your preference.

As standard, Aviramps use Hatz engines.

Yes, a charging port is located towards the rear of the unit.

The chassis is made of galvanised steel and the ramps are made of aluminium

All of our ramps are manufactured with aluminium patented anti slip flooring.

The SWL on the ramps is 326KG per sq m and 150KG UDL on the crew stairs

We offer a turnaround toolbox solution for stowage on the ramp – see our optional extras.

There are a variety of options available for all models of Aviramp – see https://aviramp.com/optional-extras/ for further details.